This technique involves construction of loadbearing columns made from gravel or crushed stones with a vibrator to reinforce all soils in the treatment zone and densify surrounding granular soils. It’s a technique first developed by our company founder, Johann Keller, that we’ve used on thousands of projects since.

Common uses

Process

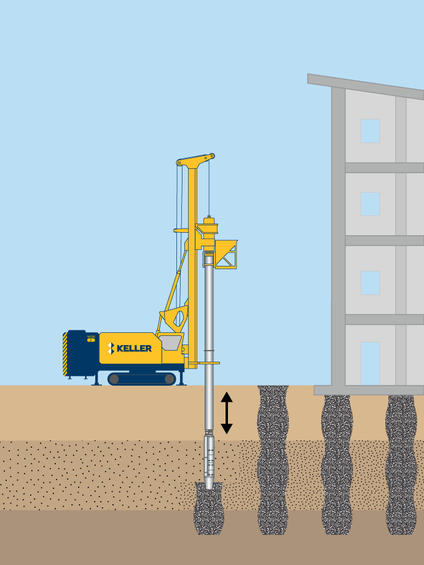

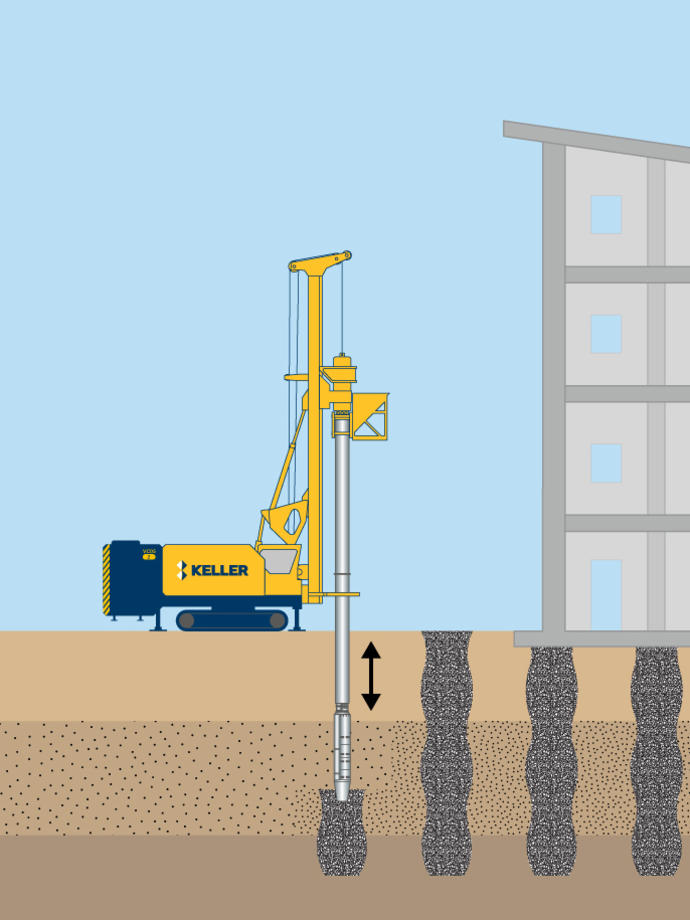

Dry bottom-feed method

The dry bottom-feed process feeds stone to the vibrator tip through an attached feed pipe. Pre-drilling of dense strata at the column location may be required for the vibrator to penetrate to the design depth. This method of construction creates a high modulus stone column that reinforces the treatment zone and densifies surrounding granular soils.

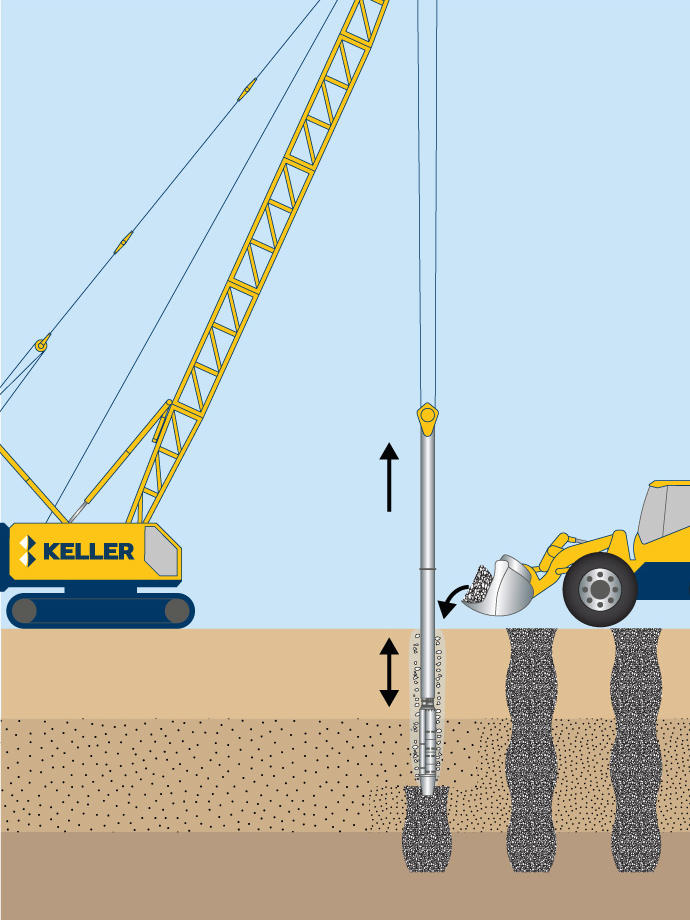

Wet top-feed method

In the wet top-feed process, the vibrator penetrates to the design depth using the vibrator’s weight and vibrations, as well as water jets located in the tip. The stone (crushed stone or recycled concrete) is then added at the ground surface to the annular space around the vibrator created by the jetting water. The stone falls through the space to the vibrator tip and fills the void created as the vibrator is lifted several feet. The vibrator is lowered, densifying and displacing the underlying stone. The vibro replacement process is repeated in lifts until a dense stone column is constructed to the ground surface.

Dry bottom-feed method

Wet top-feed method

Advantages

Quality assurance

The vibro equipment we use is designed and manufactured by our in-house equipment manufacturer exclusively for use by Keller companies.

In-house quality production manager software enables us to capture and analyse data in real time and validate the performance of the ground improvement being carried out.

A variety of production parameters are generally logged during execution including depth, current, pull down force, uplift/pull down sequence, time and date and element number.

Field trials can also be used to verify column production parameters, along with static load tests, single or group, column material compressive strength tests, and column diameter verification.