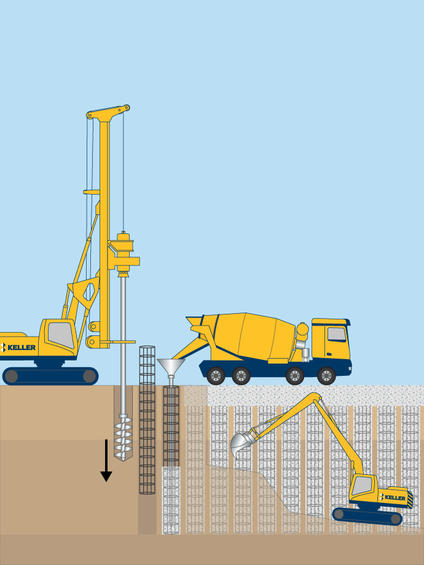

Contiguous pile walls consist of piles arranged in a way that a gap remains between the piles. Where required the soil between the piles can be stabilised during excavation by either installing timber lagging in front of the excavated soil or by building a reinforced shotcrete wall towards the excavated soil surface. Alternatively, injection grouting can be carried out in advance of the excavation in order to solidify the soil between the piles.

Common uses

Process

Contiguous pile walls retained by anchors or strutting systems are often supported by a waler beam to distribute the loads (and prevent anchors/struts from punching through the infill) and as a mitigation measure for the unlikely event of an anchor/strut not carrying the load. This waler beam can be constructed as a reinforced concrete beam casted towards the pile wall, or by using steel profiles fixed to the piles and anchors/strutting systems.

Advantages

Quality assurance

We use the latest technology, testing regimes and best practices protocols developed over many years to ensure the position, verticality and structural integrity of our pile walls.