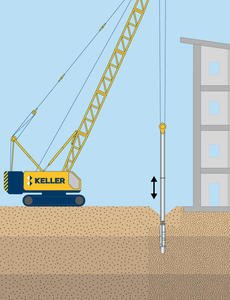

Ground improvement

Ground improvement can increase load-bearing capacity, reduce settlement and improve the engineering properties of existing soils.

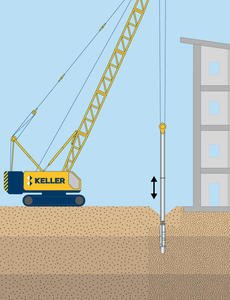

Heavy foundations

Heavy foundations are required whenever weak soils have little capacity to resist an existing load or a change in existing load. They involve the construction of structural elements to transfer loads down to stronger underlying soils or rock.

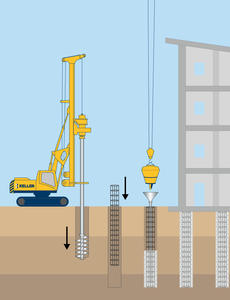

Earth retention

Earth retention retains earth successfully so that it does not move or shift to any unwanted directions.

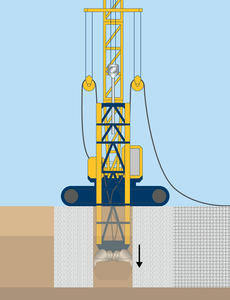

Grouting

Keller leads the world in grouting technology with systems for all applications from lifting structures to grouting dam curtains.

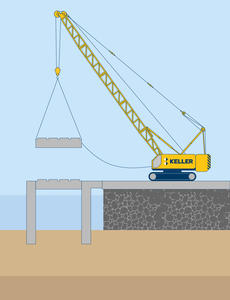

Near shore marine